PLC Programming Languages

PLC programming is the foundation of industrial automation, allowing engineers to control machines, processes, and production lines efficiently. Unlike traditional programming languages, PLC programming is designed for real-time control and monitoring in industrial environments.

This page will cover:

- ✅ Fundamentals of PLC Programming

- ✅ Common PLC Programming Languages (IEC 61131-3 standard)

- ✅ Best Practices for Writing Efficient PLC Code

- ✅ Real-World Examples of PLC Programming in Action

Whether you are a beginner or an experienced engineer, understanding PLC programming is crucial for designing efficient, scalable, and reliable automation systems.

1. Fundamentals of PLC Programming

PLC programming involves writing instructions that control machinery and processes. The program is executed in a cyclical scan mode with four primary steps:

- Input Scan – Reads the status of sensors and input devices.

- Program Execution – Executes control logic based on input conditions.

- Output Scan – Updates actuators, motors, and output devices.

- Housekeeping – Internal diagnostics and communication with other devices.

Example: Basic PLC Operation

Imagine a conveyor belt system in a manufacturing plant:

- 👉 A sensor detects an object, triggering the PLC to turn on the motor.

- 👉 Once the object moves to the next station, another sensor signals the PLC to stop the motor.

This automation improves efficiency and reduces manual intervention.

2. Common PLC Programming Languages

PLCs use programming languages standardized under IEC 61131-3, ensuring consistency across brands like Siemens, Allen-Bradley, Schneider Electric, and Mitsubishi.

A. Ladder Logic (LD)

- ✔ Most popular PLC programming language

- ✔ Graphical representation similar to electrical relay circuits

- ✔ Easy to understand for electricians and automation engineers

Example: Ladder Logic for a Conveyor Belt

How it Works?

- Pressing the Start Button (Normally Open Contact) energizes the Motor.

- Pressing the Stop Button (Normally Closed Contact) de-energizes the Motor.

🔹 Best for: Simple on/off controls, safety interlocks, and relay logic replacement.

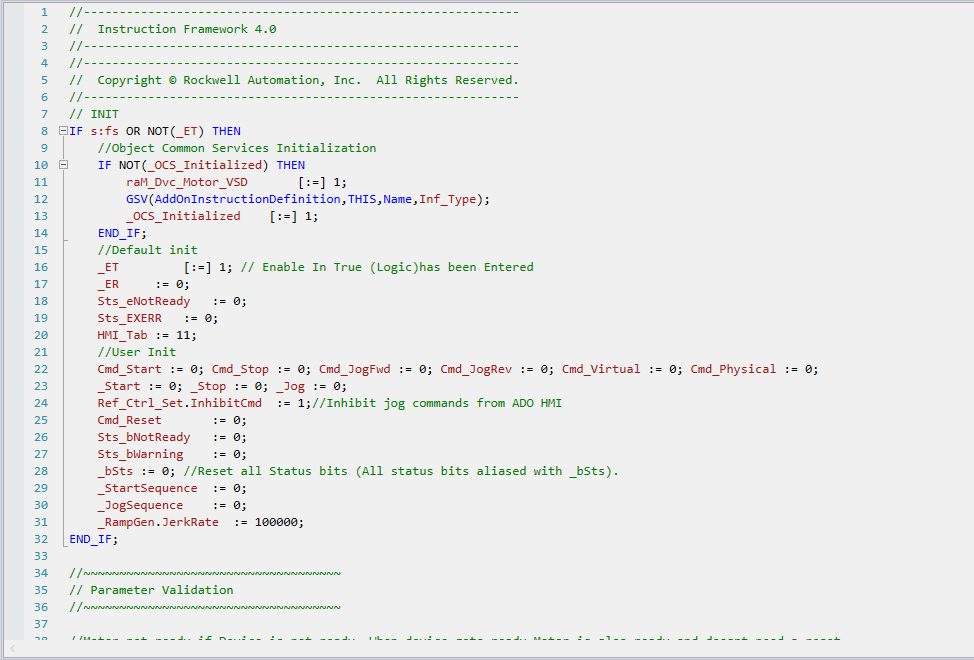

B. Structured Text (ST)

- ✔ Text-based, similar to Pascal or C

- ✔ Best for math, loops, and conditional logic

- ✔ More compact and powerful than Ladder Logic

Example: Temperature Control in ST

How it Works?

- If the temperature exceeds 100°C, the fan turns ON.

- Otherwise, the fan remains OFF.

🔹 Best for: Complex math operations, algorithms, and process automation.

C. Function Block Diagram (FBD)

- ✔ Graphical language using functional blocks

- ✔ Easy visualization for complex logic

- ✔ Widely used in process automation and batch control

Example: Motor Control Using FBD

🔹 Inputs: Start Button, Stop Button

🔹 Outputs: Motor

How it Works?

- Start button pressed → Motor ON

- Stop button pressed → AND function blocked → Motor OFF

🔹 Best for: Sensor-based control and modular automation.

D. Sequential Function Chart (SFC)

- ✔ Step-by-step process control

- ✔ Common in batch processing, packaging

- ✔ Graphical flow representation

Example: Bottle Filling Process in SFC

🔹 Best for: Multi-step processes like pharmaceutical production.

E. Instruction List (IL)

- ✔ Low-level, assembly-like language

- ✔ Compact and efficient

- ✔ Best for legacy systems and speed-critical apps

Example: IL Code for Motor Start/Stop

🔹 Best for: Compact control and high-speed execution.

3. Best Practices for PLC Programming

- ✔ Modular Programming – Break logic into reusable function blocks

- ✔ Comment Code – Add notes for future troubleshooting

- ✔ Descriptive Names – e.g.,

Start_Buttoninstead ofX1 - ✔ Error Handling – Add diagnostic checks and fallback logic

- ✔ Optimize Scan Time – Eliminate inefficient loops and delays

4. Real-World Applications

- ✅ Automotive: Robotic welding and painting

- ✅ Food & Beverage: Bottle filling and labeling

- ✅ Energy: Power regulation in grids and renewables

- ✅ Water Plants: Dosing and filtration automation

- ✅ Manufacturing: Conveyor systems and sorting

Example: Car Assembly Line – Sensors trigger robotic welding → Car moves to next station → PLCs ensure high efficiency.

Key Takeaways

- ✔ Ladder Logic (LD) – Best for on/off logic

- ✔ Structured Text (ST) – Great for logic-heavy apps

- ✔ FBD – Ideal for process visualization

- ✔ SFC – Step-by-step automation

- ✔ IL – Compact code, legacy system use

PLC Programming Languages Comparison Report

Compare common PLC languages by characteristics and suitability:

| Feature | Ladder Logic | Function Block Diagram (FBD) | Structured Text (ST) | Instruction List (IL) | Sequential Function Charts (SFC) |

|---|---|---|---|---|---|

| Visual Representation | Graphical, relay diagrams | Function blocks | Pascal/C style text | Assembly-like text | Stages and transitions |

| Ease of Use | Easy | Good, but can be cluttered | Requires coding skills | Efficient, but tough | Good for sequences |

| Best For | Discrete control | Modular processes | Math & algorithms | Speed-critical apps | Multi-step control |

| Strengths | Intuitive, supported | Modular, reusable | Powerful, flexible | Compact, fast | Process visualization |

| Weaknesses | Not for complex systems | Visually cluttered | Harder for non-coders | Hard to maintain | Not ideal for non-linear logic |

As technology evolves, PLC programming will merge with AI, IoT, and cloud platforms, transforming smart factory automation.